AI Operations Data Solutions

We understand that success in heavy industry - including manufacturing - hinges on mastering multifaceted operations across resource extraction, material transportation, production lines, and logistics. Our Operational Data solutions consolidate diverse information into practical, performance-focused results that enhance both efficiency and profitability.

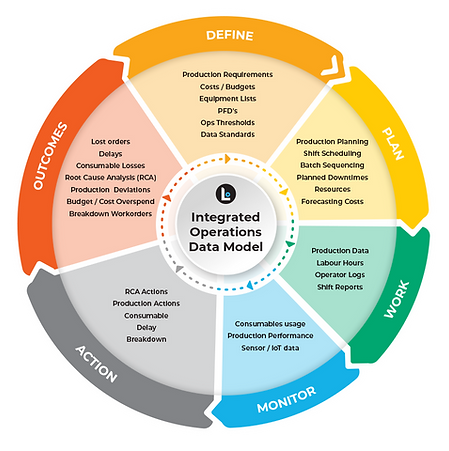

INTEGRATED OPERATIONS DATA MODEL

All Libero AI operational data solutions employ our Integrated Operations Data Model (IODM) to transform how you gather and utilise operational data - resulting in improved efficiency, and overall performance.

This approach provides improved perspective on your entire production effort, allowing you to quickly detect emerging operational issues and mitigate potential risks to both equipment reliability and process throughput.

IODM Process:

-

Define: Clearly articulate your operational scope, objectives, constraints, and identify critical failure modes or bottlenecks.

-

Plan: Develop production strategies, schedule tasks, and align materials, labor, and spare parts to support optimal operations.

-

Work: Execute daily production tasks capture all relevant operational data in real time.

-

Monitor: Continuously track production metrics and performance; detect anomalies for early intervention.

-

Action: Implement and coordinate targeted actions—process adjustments or resource redeployment—and ensure closed-loop feedback.

-

Outcomes: Capture all unplanned events— cost overruns, production delays—and quantify their impact, feeding learnings back into continuous improvement.

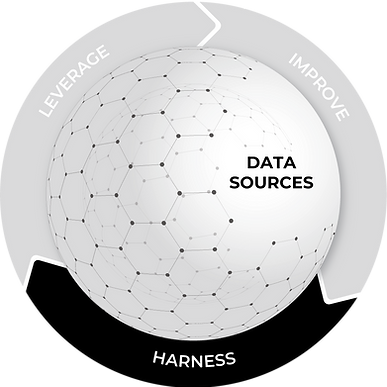

THE AI OPERATIONS DATA JOURNEY

PHASE 1

IMPROVING YOUR OPERATIONS DATA

Improving data quality is the essential first step to improved operations performance.

Aggregating and standardising data between operational systems into unified formats eliminates data silos and allows information to flow more easily across teams, enabling better collaboration, faster decision-making, and a clearer understanding of overall operational performance.

The phase utilises the following AI / analysis methods:

-

Neural Embeddings

-

Automated Data Reconciliation

-

Agents

REAL-WORLD APPLICATION EXAMPLES:

-

Convert operational metrics into vector representations that capture similarities between terms, systems, or processes (e.g., “H2O Flow” vs. “Water Throughput”), reducing manual cleanup.

-

Employ intelligent rule-based engines and machine learning to detect and correct inconsistencies - such as missing fields - preventing flawed inputs from propagating downstream.

-

Integrate with multiple legacy databases or APIs, automating data collection.

PHASE 2

HARNESSING YOUR OPERATIONS DATA

Once your operations data quality at capture is improved, we help harness it.

By integrating data sources, we provide supervisors with real-time visibility over machinery, staff deployment, and safety metrics. AI-driven optimisation integrates rosters, equipment, and timelines, assisting resource availability and compliance with exposure guidelines.

The phase can utilise the following:

-

Mathematical Modelling

-

Machine Learning

-

Queueing theory Analytics

REAL-WORLD APPLICATION EXAMPLES:

-

Constraint-based optimisation (linear/integer programming) to allocate staff, equipment, and tasks.

-

Learns from historical scheduling patterns to suggest more efficient staff-machine-task assignments.

-

Model how tasks move through different stages (e.g., raw material loading, processing, packaging), identifying hidden bottlenecks and guiding load balancing.

PHASE 3

LEVERAGING YOUR OPERATIONS DATA

Once your operations data is harnessed, our AI solutions help leverage it to provide actionable insights.

With real-time visibility into production metrics, AI tools identify inefficient processes - such as prolonged machine idle times or bottlenecks in specific operational tasks - and recommend quick changes, like reassigning staff or adjusting production sequences.

The phase can utilise the following:

-

Bayesian Optimisation

-

Graph Analytics

-

Mathematical Modelling

REAL-WORLD APPLICATION EXAMPLES:

-

Continuously fine-tune process parameters (e.g., cycle times, feed rates) to strike the best balance between speed, quality, and cost as new data emerges.

-

Visualise the flow of materials or tasks across connected facilities, revealing hidden choke points or resource dependencies that might hinder overall performance.

-

Simulation or optimisation to propose changes in task sequencing.